Product Description

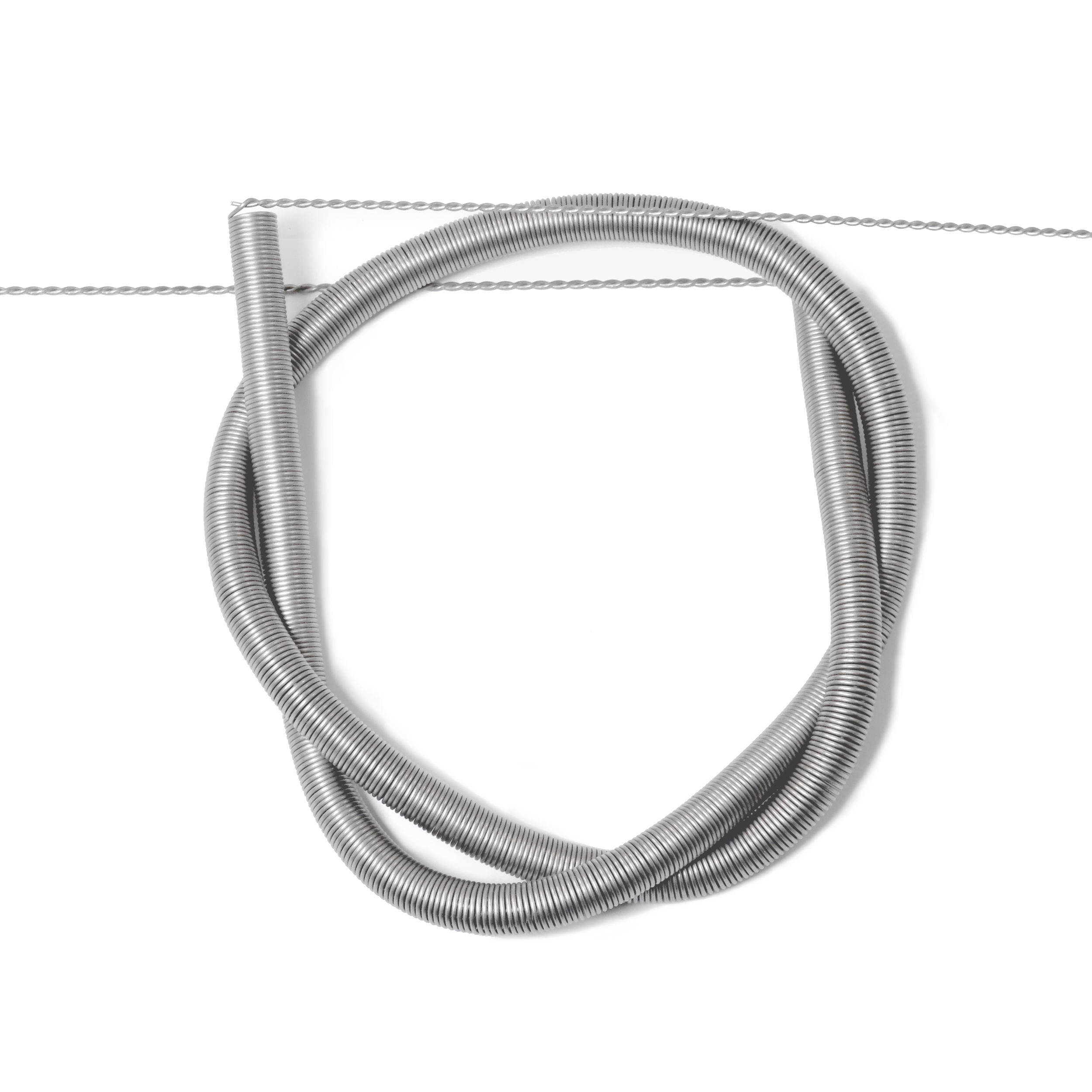

These are coiled wire heating elements (see Special Note below) which are used in many applications such as ceramic kilns, glass kilns, glass annealers, and many more do-it-yourself projects. The coiled element can be stretched to its "Installed length" and formed to fit many applications.

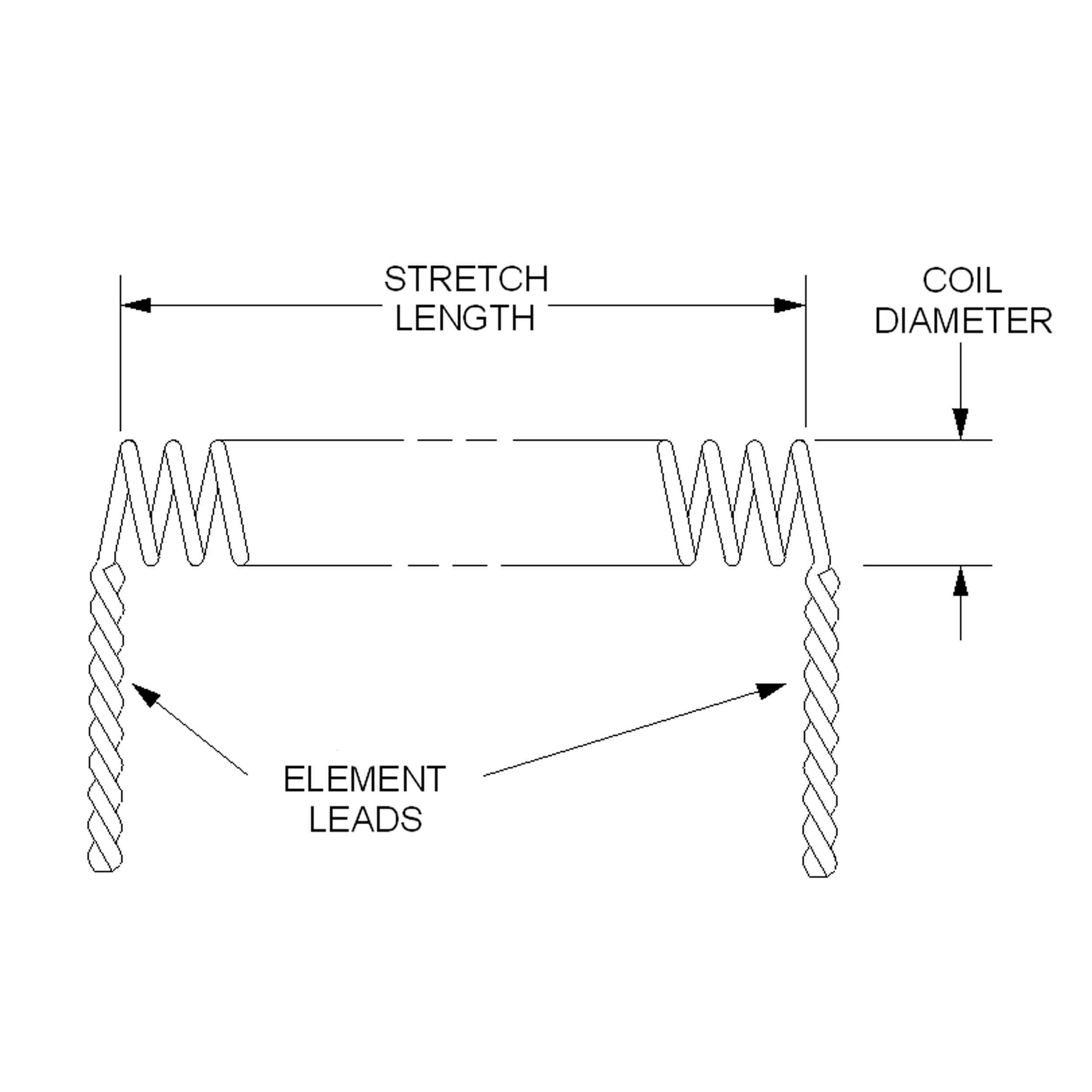

Element Dimensions: (see element sketch)

Coil Diameter: This is the outer diameter of the coiled element.

Stretch Length: Elements are shipped close wound. They must be stretched out to the recommend "Installed length" for normal operating performance. Do not cut any of the element coils, as it will alter the performance of the heating element.

Element leads: All elements come with twisted leads (10 in long) for electrical connections. The twisted leads can be cut shorter to suit the application.

Element Wire: The Element wire is Kanthal A1, 875 alloy or equivalent, using 13-16Ga wire. The typical wire loading is 18 Watts/sq in or less making it suitable for uses up to 2000°F

Element Coil Stretching Instructions:

Tools Required: • Tape measure • Bench vise • Locking pliers • Safety Glasses

Make sure you are wearing safety glasses in case the element slips from vise or pliers. Stretching an element is a little bit of a trial-and-error process. If you have a long bench with a vise, you can stretch elements with one person, if not you will need two people. Mark out the element’s installed length by measuring from the end that is held fixed. Firmly clamp the fixed end in position, and then pull the heating element 10% beyond your installed length. Note the distance where you stretched to, then allow the element to relax fully. Very likely you will not have stretched it far enough. Now stretch slightly beyond your first stretch mark. Mark the spot again where you stretched to. After you have done this several times, you will quickly determine how far you must stretch an element to obtain the desired installed length. If you overstretched the element there are a few ways to correct this. If you are only slightly beyond your installed length, loosely shaking the element with the fixed end still clamped will usually reduce the length due to memory effect. If you are well beyond the installed length and shaking will not reduce the length sufficiently, you will have to compress and re-stretch the element. If necessary, you may have to run a rod down the interior of the element in order to compress it enough without extreme distortion. Remember, never cut element shorter to fit it into your kiln. Cutting coil turns out of an element will cause elements to draw more amperage and run hotter. In the best case you will shorten its working life; in the worst case you may cause a fire.

Special Note: ELEMENTS FOR PROFESSIONAL USE ONLY:

These elements are intended for use by repair professionals and kiln builders with an understanding of electrical principals such as OHM's LAW and electrical safety codes. Many kilns have different element specs depending upon element location and wiring configuration. These elements are not returnable because when they are assembled or installed, we have no way of knowing if they have been damaged. We cannot resell a heating element that has been returned and take the chance we are sending a customer a damaged product.